US $299.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Manufacturer | Kurt |

Directions

Similar products from Grips & Tongs

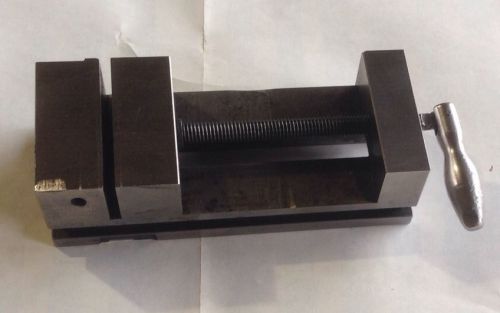

3-1/2" INCH ULTRA PRECISION TOOLMAKER'S VISE

SHOP FOX 4-1/8" x 90 DEGREE ADJ ANGLE VISE 15 DEG INDEX 3-3/4" CAP NEW D2933

SOBA Precision Self Centering Bench Vise - 3-1/4" Jaw Width x 5" Opening

4" PRECISION VISE FOR MILL, MILLING MACHINE, GRINDING, WIRE EDM M2021123 NEW!

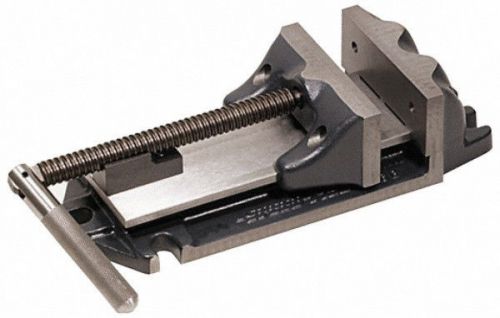

9D52 VISE, 4" WIDE & 3-1/2" OPENING, MADE IN TAIWAN, 9-1/2" X 6" X 2-1/2" CLOSED

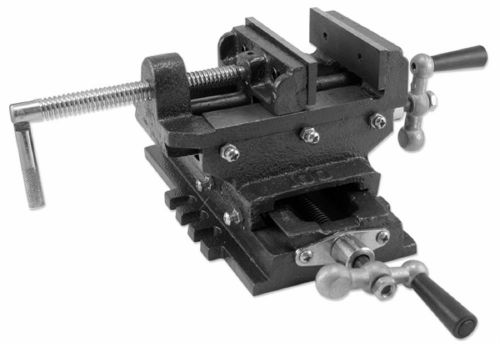

4" Cross Drill Press Vise Slide Metal Milling 2 Way X-Y Clamp Machine Heavy Duty

9D59 VISE, 2-3/4" X 1-7/8" JAW, 3" OPENING, YANKEE #1993, 360 SWING, NORTH BROS

TE - CO USA Deluxe 52 Pc. Clamping kit All NEW 7/16 Slot 20412 USA MADE

4 -1/2" VINTAGE COLUMBIAN 504-1/2 MACHINIST VISE REPLACEABLE 4 -1/2" JAWS USA!!

Craftsman swivel Vise model 506-51800 3.5 inch 17 pounds anvil

Kurt Vise Jaws-Aluminum Step Jaws--Jaw Size 1" X 2" X 6"--Step Size--1/8" X 3/8"

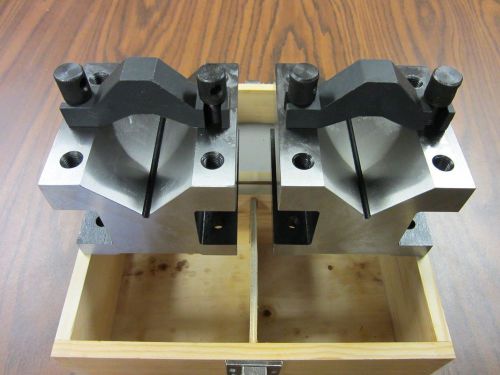

4-1/8" PRECISION V-BLOCK PAIR W. CLAMPS part# 706C-755--New

1/4" thick precision steel parallel set 9 pairs/set 0.0002" accu. #703-1/4--new

1-2-3 inch precision block pair,0.0002" accuracy,6 pairs per order, #701-123-new

CARDINAL, 8B, 8" Drill Press Speed Vise, Jaw Cap. 9", Throat 3", Steel, /GQ4/

Kurt Vise Jaws 1" X 3" X 6"Sine Angle Jaws-Original design-5 min. S/U

Aloris Distributon Catalog 56 Page MADE IN THE USA

6inch Quick Change Aluminum Soft Vise Jaws CNC, HAAS, FADAL, MORI, KURT,

Wilton 14305 408Sf 400-Sf Series C-Clamp 0-Inch-8-1/4-Inch Jaw Opening 5-Inch

People who viewed this item also vieved

NEW Hardinge Special B60 Index Collet 27/64 inch Round Brown & Sharpe 23

ER16 collets 10pcs from 1mm to 10mm for CNC Chuck Milling Lathe

ER11 collets 7pcs from 1mm to 7mm for CNC Chuck Milling Lathe

36.75" x 16.25"x5.25" Steel Welding T-Slotted Table Cast iron Layout Plate Weld

V-ANGLE STEP PLATE TOOLMAKER PRECISION GROUND INSPECTION 4.25X4.04.0

Irwin 225105 Quick-Grip C-Clamp-5" C-CLAMP

Brown & Sharp Parallel Clamps set of 6

SET OF THREE CUSHMAN CHUCK JAWS

SET OF THREE 18A HURON CHUCK JAWS

JACOBS 11N BALL BEARING SUPER CHUCK 0 - 3/8 Cap. w/2MT NICE! *

USED RITEN USA THREADED END #14 JARNO LATHE DEAD CENTER (1.150"-Point Diameter)

New MT3 Lathe Dead Center Morse Taper #3 Lathe Center

ROHM GERMANY! PRESICION BALL BEARING LIVE CENTER W/ 4MT SHANK 108H MK4

New Noble Kawatatec Machining center pallets 800-A PL-5 Kitamura Mycenter HX800

V BLOCK $ CLAMPS extra large will hold a 4 inch round part

8" Aluminum Soft Jaws 1.5mm x 60° Serrated for B-208 Type Lathe Chucks (3" HT)

MACHINIST TOOLS LATHE MILL Machinist Lot of V Blocks for Holding Set Up

Machinist Pair Of 1" -2" - 3" Blocks Hardened & Ground

10 Inch Yuasa Rotary Table # 550-110, Free Ship. Machine Shop Tool

MACHINIST TOOL LATHE MILL Machinist Palmgren ? 3 Axis 8" Rotary Table

Haas Servo Control Brush 17 Pin *Tested Warranty* HA5C HRT 210 310 160

METAL LATHE MACHINIST JACOBS 96-05 FLEX COLLET CHUCK WITH SEVERAL FLEX COLLETS

DA-100 Double Angle Collet Chuck 1" Straight Shank 7-1/4" Long DA100

Royal Products P/N 43366, Cnc Heavy Duty Bar Puller

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies