US $149.00

| Condition | For parts or not working

:

An item that does not function as intended and is not fully operational. This includes items that are defective in ways that render them difficult to use, items that require service or repair, or items missing essential components. See the seller’s listing for full details.

|

| Seller Notes | “can not test 3 phase 208V/360V Motor” |

Directions

Similar products from Lab Fermenting Equipment

B. Braun Biotech Sartorius Digital Benchtop Biostat i Twin Controller

B. Braun Biotech Sartorius Biostat i Interface w/ Heidolph Motor

Chemap Fermenter Impeller Stainless Steel

Chemap Pressure Fermenter Jacketed Bio Reactor Stainless Steel 316L 7 liters

2011 Parr Apparatus 3921 Hydrogenator with 2 Liter Chamber Tested with Warranty

B. Braun Biotech Bioreactor/fermenter, DCU Touch,Biostat B-DCU, Sartorious RQS

B. Braun Biotech, Biostat B-DCU fermentation tower, Sartorious RQS

Stainless Steel 316L Reactor Fermenter Shroud Cover Shield Hood

NEW BRUNSWICK BIOFLO 110 FERMENTOR WITH HEAT EXCHANGER

Pressure Fermenter Reactor Stainless Steel 9 hole Headplate cover 220mm diameter

Fermenter Reactor Baffle Stainless Steel 316L

New Brunswick BioFlo 4500 Fermenter,Fermantor, Bioreactor

FERMENTOR REACTOR CHAMBER NICE LARGER ONE

FERMENTOR REACTOR CHAMBER NICE

Sartorius Stedim Systems 3 channel inoculation kit (for bioreactor/fermentor)

New Brunswick Celligen Blu Disposable Bioreactor

DCI 225 Liter Jacketed Bio-Reactor, Stainless Steel Tank w/ 50 PSI Max Pressure

DCI 225 Liter Jacketed Bio-Reactor, Stainless Steel Tank Max Pressure @ 50 PSI

DCI 225 Liter Jacketed Bio Reactor, Stainless Steel Tank Max Pressure @ 50 PSI

CPC Cytos Microreactor Lab System

People who viewed this item also vieved

Uniphase 1103 Laser w/ 1201-1 Power Supply No Output For Parts AS IS

Cole-Parmer pH Controller/Recorder w/ 672 Analyzer & Great Lakes 280 57505

++ Nikon BD Plan 40 0.65 210/0 OBJECTIVE (#2)

Ultrasonic heath sonic Hu-Friedy T3-3C, dental shaker, ultrasonic cleaner

Siemens Advia Centaur CP MOTOR X PROBE 10309686

Welch Allyn ® Panoptic OphthOphthalmoscope 11820

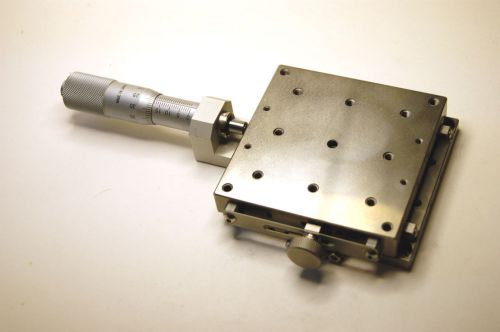

Japanese 80mm x 80mm X axis Linear stage stainless # S-AG-76

Reichert lens Apo 2mm.,tube length 250mm. Attachment 25.3mm(1 inch)

Agilent/Velocity 11 06118-001 V-Prep peristaltic pump module V works automation

HYBRIDIZATION INCUBATOR LABGO AA18

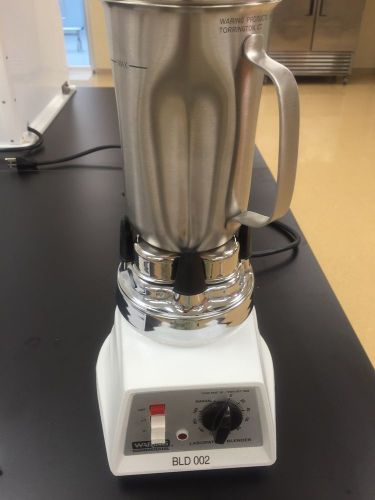

Waring 7010BU Lab Bench Top 2-Speed Commercial Blender Mixer W/Container (2)

Cole Parmer Variable Speed Stirrer 115VAC

LEICA REICHERT-JUNG 2030 BIOCUT MICROTOME

Midmark M9/11 CPU Mother Board P/N 002-0762-00

Prior Optiscan Focus only controler ES10ZE microscope

Thermolyne Type 50800 Roto Mix Orbital Shaker 8 x 8 Inch

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies