US $105,500.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | CMX Process Technologies (Axomatic) |

| Model | Axomix 50L |

Directions

Similar products from Plastic Mixing Tanks & Accessories

Mixer Philadelphia Gear 25 HP Model HVS-25 Serial # 35037-1 Silver Streak

Bulling Stainless Steel Reactor Vessel

1.45 Liter W & P Lab Internal Rotor Mixer

Dayton Laboratory Drum Lab Mixer, 1/20 HP, Stainless Steel 32V142

HAAKE 001-9758/194017956002 RHEOCORD 9000 FISONS RHEOMETER MIXER, USED

NEW ! Scilogex D160 Handheld Homogenizer w/Stand &10mm Probe, 1-250ml, 85010201

NEW! Scilogex D500 Handheld Homogenizer w/Stand &20mm Probe 10-50,000ml 85020101

Shini 4 Component Material Blender, Model SGB-80-4, 2010 Vintage

NEW MADE TO ORDER 10 LITER CMX/AXOMATIC MINIMIX HOMOGENIZER MIXER - 316 L S/S

NEW MADE TO ORDER 5 LITER CMX/AXOMATIC MINIMIX HOMOGENIZER MIXER - 316L S/S

NEW MADE TO ORDER 3 LITER CMX/AXOMATIC MINIMIX HOMOGENIZER MIXER - 316L S/S

Lightning Mixer .43 HP With 30 Gallon Tank

Agitator turbine mixer high capacity process equipment blender reactor blade

1 1/2" FERREL STEEL STATIC MIXER HMI-C1.5

16 Qt Patterson Kelley Twin Shell Dryer Blender

LIGHTNIN V5P18 VEKTOR CHEMICAL AGITATOR MIXER .25 HP 115/230V 1PH

DA06 FITZMILL - S/S - SCREW FEED

Fluid Automation / Graco Model 201-G, 55 gallon drum Silicone pump, main pump

Mixer Agitator Shaft With Mixer Disc, Stainless Steel

People who viewed this item also vieved

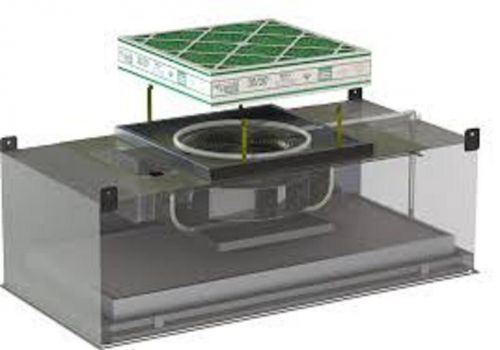

CAMFIL FARR PHARMASEAL FFU FAN POWERED CEILING CLEANROOM LAB DIFFUSER HOOD NEW

Pro-Log Spectroline UV Eraser 9103A

GOYEN CONTOLS COIL100V/120V 50/60HZ

Switch BRADFORD 625AKRMQE, 2KOT032699, E22043ISP THERMAL SWITCH, HEATER RM

Pump CTI-CRYOGENICS 8107819G001 8F Cryo Pump

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies