US $79.99

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Model | End mill for Aluminum |

| MPN | RXC753 |

Directions

Similar products from Other Cutting Equipment & Expendables

ARNO BORING BAR EC-ADX20-08 1023206453/01

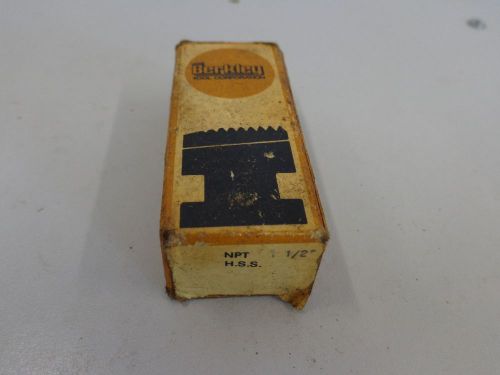

VARGUS 3/8" NPT THREAD CHASERS

New Lathe Alignment Test Bar 4MT 8 29/32" Taper Shaft 1.25inch

BRAND NEW KORLOY SPBA 125 GROOVING TOOL

GEOMETRIC 7/8-14 NF THREAD CHASERS FOR 3/4 D

Center Cutting HP HSS Finishing End mill 1-1/2x1-1/4x6x8-1/2 TiCN Square End 3FL

GEOMETRIC 3/8 NPT THREAD CHASERS FOR 3/4 D

HUGE LOT OF CAMLOC 11mm - 1/2 - 3/4 BACK ANNULAR SPOTFACERS W/ 6mm SHANKS

VARGUS 1-1/2" NPT THREAD CHASERS

6” carbide tipped divider, 4 “ carbide tipped divider, 6”, toolmakers divider

Stanley 9-1/2 Block Plane LEVER CAPS Lot of 5

Brand New Cleveland Twist Drill 5/16" Spotfacer Counterbore

SECO POLY CRYSTALLINE DIAMOND INSERT DC1384 PCD30

People who viewed this item also vieved

(10pcs) SNMG643MN KCP10 KENNAMETAL Insert

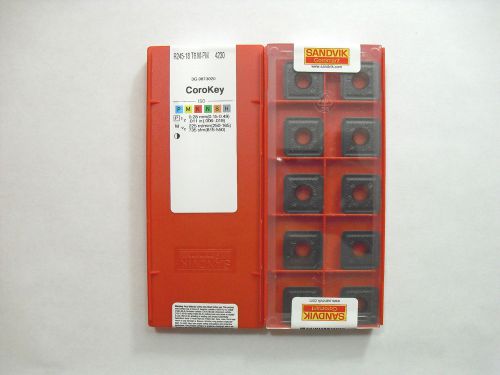

SANDVIK R245-18 T6 M-PM 4230 Insert

Lot Of 2 New Osg Tap & Die 1/2" 4 Flute Solid Carbide End Mills Tialn Coated USA

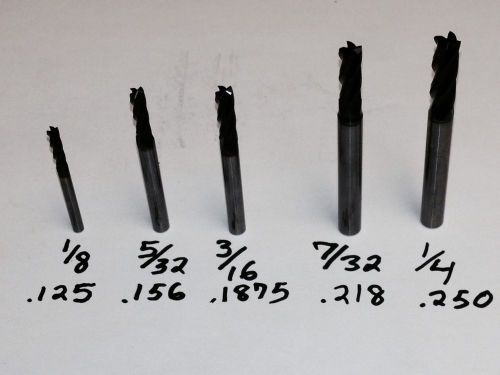

Lot Of 5 New Osg Tialn Coated End Mills 1/8" 5/32" 3/16" 7/32" & 1/4"

Williams 2-R and 2-S tool holders 3/8" bits

Overhead Valve Spring Compressor

Malco 2 3/4 x 0.128 x 1 HS Slitting Slotting Saw

LOT OF 6 HSS SAWS 1" DIA X .124WIDE X 3/8" HOLE 30T

7 PC NEW NTK TPG322 HC2 CERAMIC CUTTING TOOL INSERT LATHE MILL MILLING

Kennametal Ceramic Turning Inserts RNG 45T0420 KY2100 10 pcs NEW 225

Bully Hog ST-381 Cobalt Step Drill Bit with FREE SURPRISE TOOL!

Bully Hog ST-383 Cobalt Step Drill Bit with FREE SURPRISE TOOL!

SET OF 3 DUMONT A BROACHES 1/16" 3/32" & 1/8" + ASSORTED BUSHINGS & SHIMS

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies