US $1200

Directions

Similar products from Other Semiconductors & Printed Circuit Boards

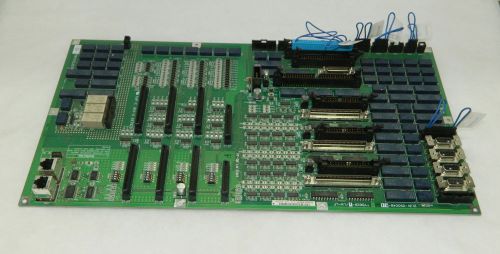

TEL TOKYO ELECTRON TYB62B-1/LM-LF

Delta Design I/0 Distribution Board Rev C

Delta Design Input Sensor Board Rev A

Delta Design Tester/Interface Board Rev B

Delta Design Output Driver Board Rev B

Delta Design X10 Output Driver Board Rev A

LUMONICS EXCIMER LASER with TRIGGER UNIT , Model 524

Delta Design Sensor Board Rev B

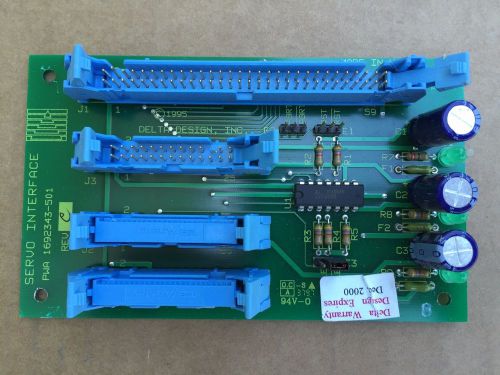

Delta Design Servo Interface Board Rev C

Edwards AIM-S-NW25 Active Gauge PN D14641000

Entegris PFA Elbows UE6T-4TFN-3

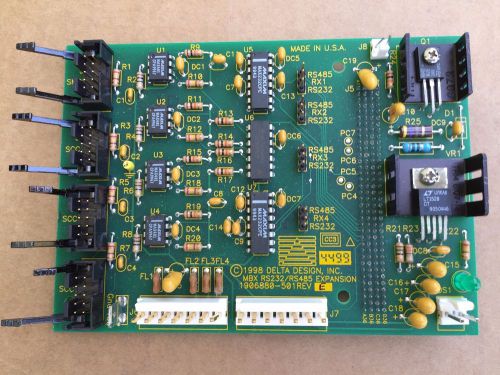

Delta Design MBX RS232/RS485 Expansion Board Rev E

Electroglas Theta Z function II Assy 245023-001

Electroglas 244288-001 244287-001 Tester Interface PCB Card

Electroglas 247265-001 Handler Communications PCB Card

Electroglas 246067-001 4 Port Serial I/O Assembly II PCB Card

Electroglas Theta Z inker Drivers Assy 244736-001

Electroglas 28V Solenoid Drivers Assy 114824-001 Card

People who viewed this item also vieved

3M 08004 Doodlebug Brown Scrub 'n Strip Pads - 20/Box

SIMCO LabRat Air Ionizer 4009928

CHEMTRONICS Ultrajet® Ultra Pure CO2 Duster System N.O.S. ES270

Vari-Speed Laminar Flow Hood 40" x 39" x 24"

6.7X-45X Zoom Stereo Microscope+Articulating Arm Stand+8W Fluorescent Ring Light

Veeco FPP-5000 4-Point Probe (Four/FPP5000) Wafer

Teradyne 5539Ci+/5539 InterScan Optical Inspection AOI System

ESD 2' x 3' Anti Static Table Work Bench Mat Matting With Grounding Cable.

Kneil ASML 4022.436.7932.2 Power Supply CL 15.8 SVG

DELTA TAU CLIPPER PLUS T3 / AXIS_LINK OPT-1 / AUX IF OPT

Universal Tape Feeder NIB ( 8mmx4mm)

MYDATA Complete Uncover Motor Unit Part # L-019-0106B

RADEON H0424 ATI Radeon 109-81100-02 Dell 03X905 3X905 0H0424 H0424 AGP Dual DV

12 Southco Low Profile, Quarter Turn Latches NEW

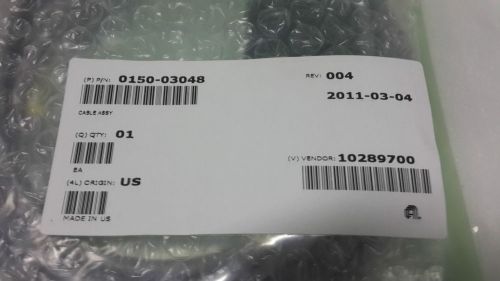

APPLIED MATERIALS CABLE ASSY 0150-03048

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies