US $1600

Directions

Similar products from Process, Temperature & Pressure Calibrators

General Radio GR 1424A Standard Polystyrene Decade Capacitor, tested good

Pressurements Hydraulic Deadweight Tester 10-500 psi Druck

Anritsu Precision Calibration Kit Used DN 7/16 OSL DC- 4.0 2000-768-R

Fluke 5100B Calibrator AC/DC DMM Digital Multi meter Amp Volt Ohm Basic Tests

EDC 521 DC CALIBRATOR SATISFACTION GUARANTEED, TESTED WITH CALIBRATED HP METER

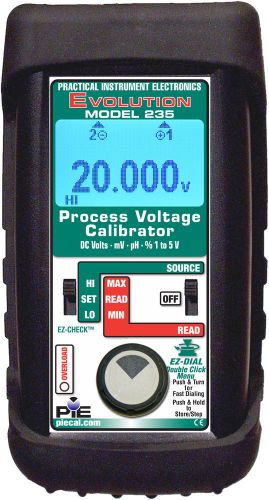

Altek 235 Process Voltage Analyzer

Altek 241 Frequency Calibrator

New Anritsu CMR137 waveguide Cal kit. 1/8 & 3/8 offset Coax to N adapter load.

Anritsu UA137 waveguide Cal kit. 1/8 & 3/8 offset Coax to N adapter load.

New Anritsu UA159 waveguide Cal kit. 1/8 & 3/8 offset Coax to N adapter load.

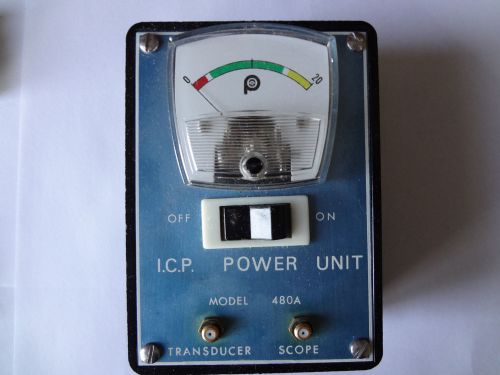

ICP Power Unit PCB PIEZOTRONICS Inc. Model 480A

Agilent HP 8485A-033 50MHz-33GHz Power Sensor, New Calib+Adapter+Cabel+Manual CD

HP 85052A 3.5mm Calibration Kit

Gilian Gilibrator 800268 800275 Kit with Thermal Printer Bubble Generator

Altek calibrator 211 replace with PIE 211 RTD calibrator

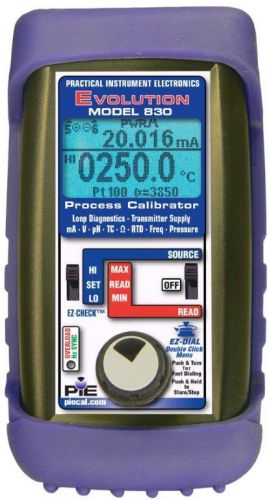

Altek 830 replace with PIE 830 multifunction calibrator

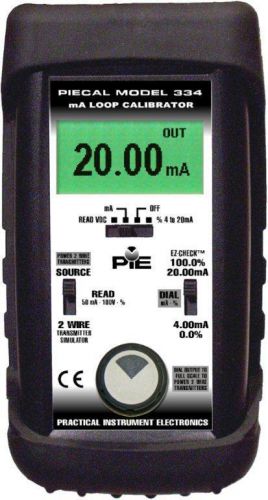

Calibrator 334A replace with PIE 334

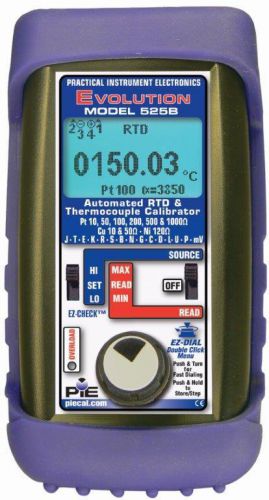

PIE 525B Automated Thermocouple and RTD calibrator

Altek calibrator 235 replace with PIE 235 voltage calibrator

PIE 422 T/C calibrator from Practical Instrument Electronics

People who viewed this item also vieved

attenuators HP. agilent precision type 2 ea.

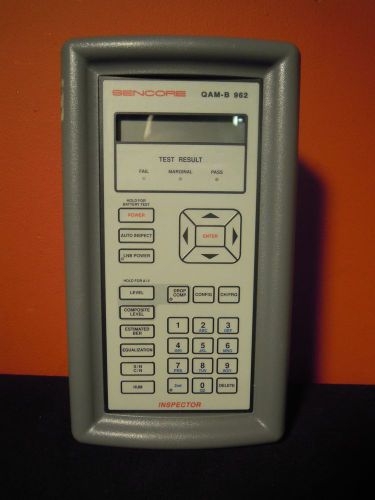

Sencore QAM-B 962 Cable Tv System Analyzer Meter

Mini Electronic Digital Red 5 Digit Hand Counter Tally

GasAlert MicroClip XT4 MC2-XWHM-Y-NA Portable Personal Gas Leak LEL O2 CO H2S

Brand New U822A Handheld Digital LCR Meter Tester 100Hz, 120Hz, 1kHz, 10kHz

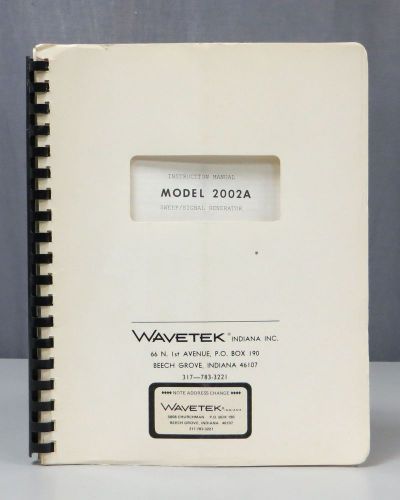

Wavetek Model 2002A Sweep/Signal Generator Instruction Manual

Sony XC-999 1/2" Hyper HAD CCD Machine Vision Camera with Cables & Power Supply

8411 TEKTRONIX TDS 420A 4 CHANNEL OSCILLOSCOPE 200 MHZ 100MS/s

RF AMPLIFIER 500MHz - 3GHz LOW POWER CONSUMPTION 12V / 50mA nod / 354

Esaote Biosound MyLab/ Siemens Ultrasound La332 Linear Vascular probe

Narda 8616 Broadband Isotropic Electromagnetic Radiator Monitor+Case&8621 Probes

Digital LCD Sound Meter Noise Level 30 ~ 130dB Freq. 31.5Hz ~ 8kHz Tester N0301

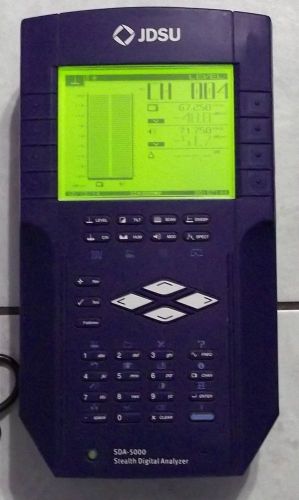

JDSU Acterna Wavetek SDA 5000 w/ Reverse Sweep #2

Ryobi IR001 Non-Contact Laser-Pointer Guided Handheld Infrared Thermometer!

Radyne ComStream High Speed Digital Video Modulator | DM240 DM-240

Schneider Eiectric Power Logic PM5500

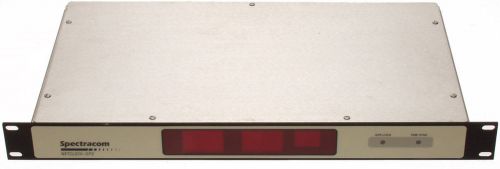

Spectracom 8183 Netclock GPS Satellite Atomic Clock Receiver 1PPS IRIG Timecode

VINTAGE HP TUNABLE BOLOMETER 475B

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies