US $130.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | TRANSBRITE |

| Country/Region of Manufacture | United States | ||

| Model | 9000 |

Directions

Similar products from Power Washers & Spare Parts

VRT3 Adjustable Unloader 4,500 PSI (Black) two

3500 PSI 4.5 GPM 5CP3120-CSS Cat Pump with Plumbing, Cat 5CP3120

NorthStar Gas Cold Water Pressure Washer 3500 PSI 4.0 GPM 50ft Hose

ColdJet AERO 30 Dry Ice Blasting Machine w/ 1 Nozzel, 120v, 140PSI

Jetstream Jet Stream 35,000 psi, 4 1/8" pressure gauge yellow face

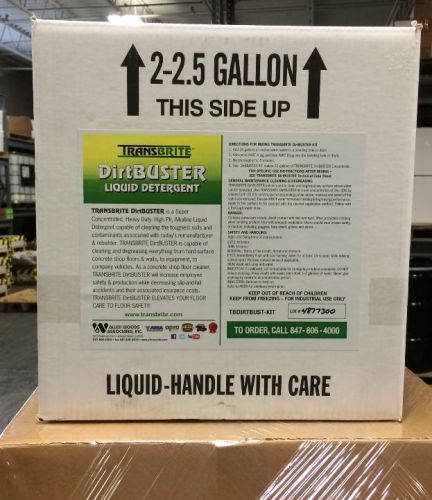

Industrial Floor Soap/Cleaner & Degreaser - TRANSBRITE DirtBUSTER

25 FT REINFORCED 4000 PSI PRESSURE WASHER HOSE KARCHER COMMERCIAL INDUSTRIAL

DEWALT 4200PSI 4.0 GPM PRESSURE WASHER

pressure washer soap tip 1/2 inch

(1) Mi-T-M HSP-3504-3MGH Hot Water Direct Drive H 3500 PSI Pressure Washer

J.E. Adams Thermal Relief Valve 1/4"MPT x 1/8"NPSF, 140 F Model 7685

Hotsy Washer High Pressure Pump

Whitco 420RS Steam Cleaning System

KaiVac 1750 No-Touch Cleaning System w/Accessories & Training Videos

People who viewed this item also vieved

JUSTRITE 27605 Cleaning/Dip Tank, Benchtop, 5 gal.

CASE 500 RED TRASH BAGS HAZARD? 15 x 9 x 23 Wholesale Case Price Liquidation

#358 New Ice Snow Scraper with warm Glove Glass Windshield Cleaner Car Auto

Bobrick (B-6637) Recessed Toilet Tissue Dispenser with Storage for Extra Roll

Pack of 3 Can WD-40 Lubricant Multi-use: 3/ 11oz Cans w/ Smart Straw

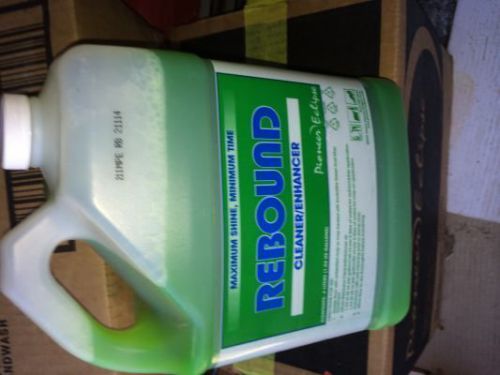

Pioneer Eclipse REBOUND (4 Bottles) Floor Cleaner & Enhancer

Continental Commercial 226-312 BL - 26-Qt Oval Mop Bucket w/ Squeeze Wringer Ca

CARLISLE FOODSERVICE PRODUCTS Mop bucket with side-press wringer. Includes one b

Copper Colored GAMCO Paper Towel Dispenser TD 2 US 10

Vintage Chrome Type R Hand Soap Borax Powder Wall Mount Dispenser Shop

NEW Tork S22 System Automatic Foam Soap Touch-Free Dispenser 572020A White

3 Tork 5555290 Elevation Bath Tissue Jumbo Roll Mini Twin Dispenser, Black

Wholesale Case 56 Rolls Bathroom Tissue Toilet Paper White New 2 Ply 500 Sheets

Pressure Washer Black Hose, 3/8 Inch x 50 Feet, 1500 psi Grainger 3JT35

4000PSI Black Pressure Washer Hose- 50' x 3/8" ID Flexible

Greenleaf Girl ~ Car Freshener Auto Vent Clip ~ Breezy Girl ~ NEW

BridgeWater ~ Car Freshener Auto Vent Clip ~ Welcome Home ~ Cinnamon ~ NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies