US $8,250.00

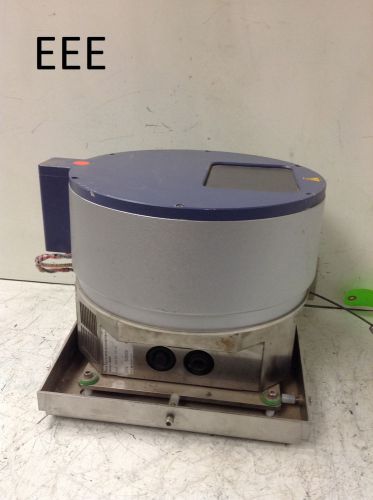

| “Good Condition and Good Working Order * Electrical modified to 220 VAC Single Phase * 2 Bowl Liners (More Available from US Centrifuges) * Some rust on inner top lid and in other places.(Clearly shown on Pictures) * Some etching/marring on centrifuge (clearly visible) * Includes Stand * Used for about 5-6 months, replaced with continuous flow centrifuge. * Very durable unit. * Serial Number W1013” |

| Brand | US Centrifuge Systems |

| MPN | M512 |

| Model | M512 Manual Centrifuge |

Directions

Similar products from Centrifugal Machines

SHANDON CYTOSPIN III CENTRIFUGE - AS IS

Hamilton Bell Electrical Centrifuge

ARJOHUNTLEIGH FLOWTRON EXCEL AC550 - AS IS

Horizon mini E centrifuge drucker 642E **LOT OF 3 ***

Hamilton Bell VanGuard V6500 Centrifuge ***LOT OF 4***

Musashi Awatron AW-20 Bubble Eliminator Centrifuge M21-1180

BECKMAN ALLEGRA 64R REFRIGERATED CENTRIFUGE WITH F1010 ROTOR

Clay Adams Becton Dickinson Compact II Centrifuge 420225

Dental Lab Impression Materials Denture Mixing Centrifuge Alginate Mixer

HAMILTON BELL VANGUARD V6500 CENTRIFUGE

THE DRUCKER COMPANY MODEL 613D LABCORP CENTRIFUGE !!! F168

Eppendorf Centrifuge model 5402 Refrigerated without rotor

QBC VETERINARY CENTRIFUGE IDEXX MODEL 4833

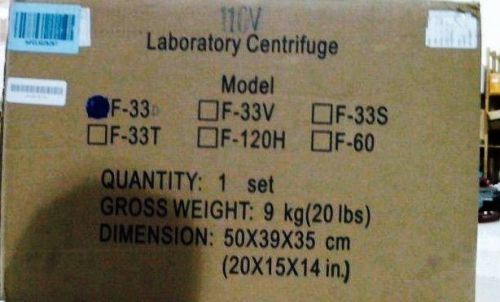

Champion Ample Scientific Variable Speed Digital F-33D Centrifuge 3300rpm 8x15ml

CLAY ADAMS QBC CENTRIFUGRE MODEL 4207

CLAY ADAMS PHYSICIANS COMPACT CENTRIFUGE MODEL 0131

Adams Physicians Compact Centrifuge CT-3300

SIAS IXION Microplate Centrifuge Robot Friendly Module 24 VDC sias centrifuge

People who viewed this item also vieved

Beckman Coulter Laboratory Ultracentrufuge Swinging Bucket Rotor SW55TI

Hermle Z 180 24 position rotor with set screw and cover

Eppendorf FA-45-24-11 24 Place Aerosol-Tight Centrifuge Rotor For 5424 & 5424R

Hermle 23026 Centrifuge Rotor Z360K w/Buckets

Sharp XG-E3500U high resolution conference series LCD Projector

SORVALL CENTRIFUGE ROTOR GSA WITH LID Model GSA-6671

![Beckman JA-25.50 Rotor [Item#16864]](/_content/items/images/76/3896476/001.jpg)

Beckman JA-25.50 Rotor [Item#16864]

![Beckman MLN-80 Rotor [Item#12088]](/_content/items/images/78/3896478/001.jpg)

Beckman MLN-80 Rotor [Item#12088]

8pc/CASE* INTERNATIONAL EQUIPMENT COMPANY IEC 320 5/81 69.5 GMS CENTRIFUGE TUBES

MICRO-CENTRIFUGE TRANSFER PIPETTE, 400/PKG

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies