US $479.00

Directions

Similar products from Tools for Milling Machines

45 DEGREE INSERT CUTTER 2 INSERTS W/ 3/4" DIA SHANK MACHINIST / TOOLMAKERS (NR)

S.T. CO HSS INVOLUTE GEAR CUTTER w/ 1" BORE - #8-7-P-12 TO 13

Weldon 3/4" End Mill F3 M2 Double ended Coated ends Looks new

Hurco Deltron Power supply 11436XC-1 P/N 4130008013 *30 Day Warranty*

Weldon 13/16" End Mill A26-4 single end 6 flute

FALCON KWIKLOK #4, COLLET HOLDER, W/ COLLETS

JACOBS 14N DRILL CHUCK, ON FALCON KWIKLOK #4 SHANK,

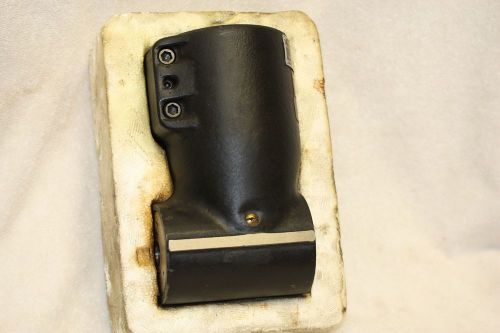

Bridgeport Right Angle Milling Head Attachment R8

kearney trecker Verticle Milling Machine

PalmGren 250 Metal Lathe Milling Attachment With Vise

ISCAR 3 Inch Diameter Face Mill with CAT40 Arbor

Bridgeport milling machine power feed electrical box

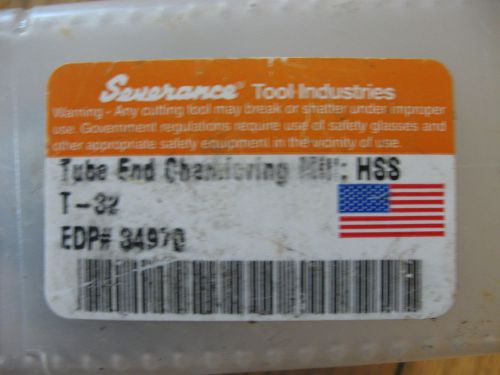

SEVERANCE Tube End Chamfering Mill 1-1/2" x 2-3/4"OAL 1/2" Shank T-32 HSS

Ingersoll 2" Hi-Pos Indexable 0° Lead End Mill (12J1D-20007S6R01)

NEW ATLAS MILLING MACHINE VERTICAL HEAD MILLING ATTACHMENT WITH 7 #2 COLLETS NEW

SPI Tram indicators for bridgeport style mill

Igetalloy Cutter - Fits Bridgeport Style Mills

Tapmatic 900x Tapping Head with Collet and Arbor

People who viewed this item also vieved

Hardinge #11 Collet 3/8" Round

Brown & Sharpe #11 Collet 3/8" Round

Hardinge and Brown & Sharpe #11 Collet 3/8" Round

JACOBS SUPER CHUCK WITH CAT 40 ATTACHED 0 TO 3/8" CAPACITY 11 N 2 JT (LOC1246B)

ACME #Y T A STD INDEXABLE SPADE DRILL .75" SHANK 24010S 075L (LOC1246B)

ACME #Z T A STD INDEXABLE SPADE DRILL .75" SHANK 240Z0S 075L (LOC1246B)

10 MACHINE DOVE TAIL CUTTERS 1'DIA. UP TO 4" DIA. MACHINE CUTTERS

SMALL SECO CARBOLOY FACE MILL 8938

Pacific J Series 75 Ton x 8' Press Brake with Hurco Autobend 5C Control

NEW Lot of (9) 2 1/2" x 6" x 72" Long Titanium Anode Baskets with (2) 5" Hooks

Century Hone Mdl CHY-BA Ball Bearing Precision Honing Machine 115V w Mandrel set

New Sunnen polishing stone set #AN 536 stones & 2 wipers

CHEVALIER 7" x 14" UNIVERSAL TOOL & CUTTER GRINDER

Chevalier 1224 Surface Grinder FSG-1224AD

Dynabrade 51800 .3 HP Angle Die Grinder 12,000 RPM 1/4" Geared

PILE OF STEEL TEMPLETS GEAR GAUGE STANDARD POSSIBLE METAL LATHE CUTTER

VINTAGE ATLAS 10" METAL LATHE TAILSTOCK ASSEMBLY

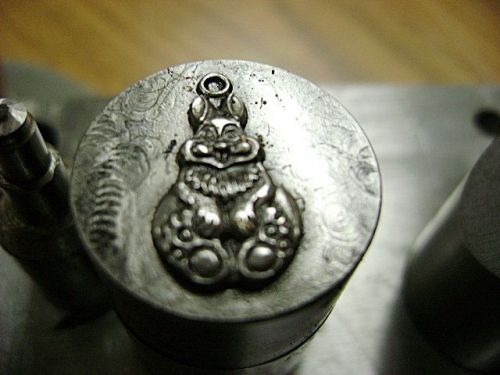

STAMPING PRESS TOOL & DIE SET TO MAKE RABBIT FINDING - Jewelry Pendant - NICE

STAMPING PRESS TOOL & DIE SET TO MAKE RELIGIOUS CROSS - Jewelry Pendant - NICE

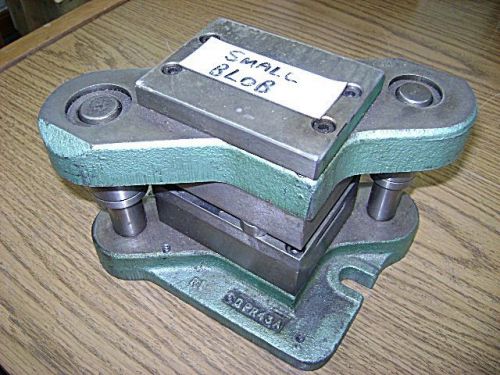

STAMPING PRESS TOOL & DIE SET TO MAKE SMALL BLOB- Jewelry Pendant - NICE

Marvel 13A PC Automatic Horizontal Band Saw w PCII Controls

Kalamazoo Horizontal Band Saw H9AW 9"X16"

System 3R 3R-610.21 Manual chuck, MacroStd FF30

System 3R EDM Work Holder, 100mm Diameter FF28

System 3R 3R-610.21-S 90842 Manual chuck, MacroStd FF29

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies