US $550.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Steel Art |

| Country/Region of Manufacture | Russian Federation | ||

| Model | vzzz_0000000095 |

Directions

Similar products from Beekeeping

Beekeeping Beekeeper Equipment Starter Kit Beekeeper Supply Tool Set Include 7pc

vintage bee book,culture,abc & xyz,Honey,apiary,farming,keeping

Bee Queen Marking Marker Cage Bottle with Plunger Beekeeping Beekeeper Tool

10 frame Complete Hive - 2 Deep Brood Boxes, 3 Honey Supers

10 frame screened bottom board painted

10 frame hive ASSEMBLED/PAINTED READY FOR BEES.

1950s Canvas France Military Beekeeper Hat Netting Mille Army Bug Net Vintage

Langstroth Deep Hive body Fully Assembled Unpainted w/ 10 Frames & Foundation

10pcs Beekeeping Bee Queen Cage Bee Match-box Moving Catcher Catching Cage

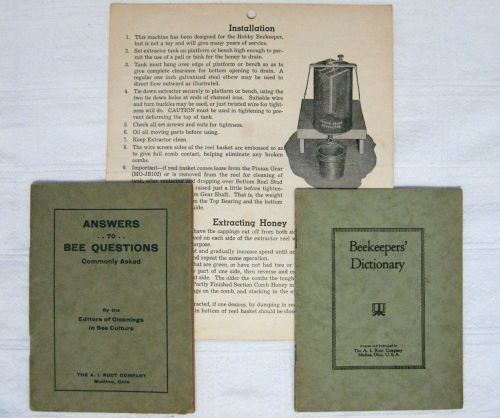

1922 "A.I. ROOT COMPANY" BEEKEEPING BOOKLETS(2) & HONEY EXTRACTOR SHEET Candle

Proven Honeybee Swarm Lure: Ten Vial 1 ML each NASONOV Pheromone w /OLD BEESWAX

Electric Honey Uncapping Knife Stainless steel HOT KNIFE Beekeeping Extractor

Warre Hive / Vertical Top Bar Hive - 4 bodies, galvanized iron roof

20 bee frames 9 1/8" Assembled with Foundation used in Beekeeping

feeder insert 10 frame hold 1 gal?

1881 BEEKEEPER'S GUIDE Honey Farm APIARY Apiculture BEEKEEPING Bee Hive ANTIQUE

Beekeeping Wire Tensioner Crimp Crimper Crimping Tool for Frame Bee Hive

5 Pcs Plastic Beekeeping Hive Tool Beekeeper Bee Keeping Honey Entrance Feeder

10x Plastic Beekeeping Hive Tool Beekeeper Bee Keeping Honey Entrance Feeder

5PCS Feeder Beekeeping Honey Entrance Beekeeper Bee Keeping Hive Tool

People who viewed this item also vieved

Orchard Garden 12M x 2.5M Black Nylon Knotted Anti Bird Mist Net 3#

0.8M Long 1.8 Metres Wide Knitting Knot Anti Bird Netting Net Green

Small Animal Nest Box Poultry Rabbits JEFFERSLIVESTOCK M3S4

6+ Rare gorgeous Lavender Orpington Chicken hatching eggs for sale!

Tension Wire Guide Clamp for 1 5/8" Line Posts - Deer and Animal Fencing

RED SNAP'R ELECTRIC FENCE CONTROLLER,MODEL LI15-15 MILE RANGE LOW IMPENDANCE

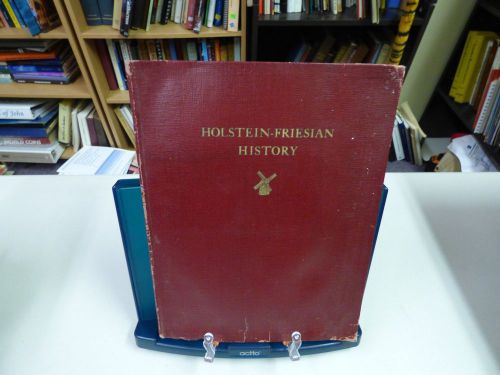

Rare Holstein-Friesian Dairy Cow History Book ( 1930)

Stainless Steel Bucket Pail Heavy Duty

18-Tray Hydroponic Fodder system w Super Duty Trays - Ready to Grow!

Vet Supply J0466 JORGY LARGE BORE FLUID TRANSFER SET Vet Stalled Horses Equine

Z Tag 25 Pack, 1 Piece, 3"W x 4-1/2"H, White, Cow Z Tag

Z Tag 25 Pack, 1 Piece, 3"W x 4-1/2"H, Yellow, Cow Z Tag

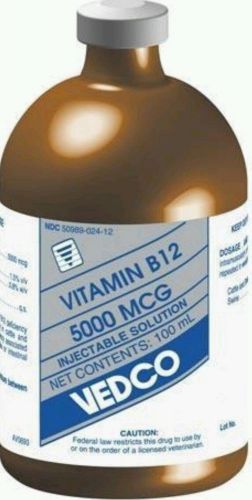

2 BOTTLES VEDCO VITAMIN B12 5000MCG/1ML INJECTABLE, 100 ML FOR VETERINARY USE

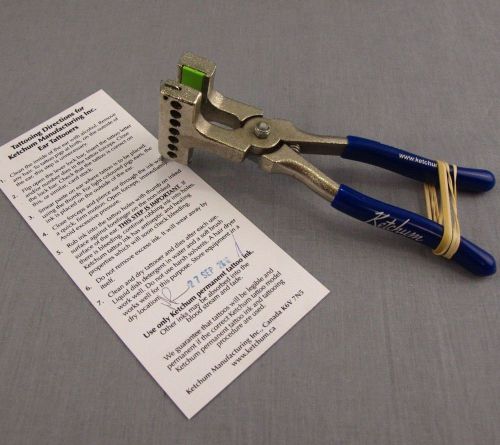

Ketchum Ear Tattooer 7-Hole Piglets Dogs Cats Rabbits 50D Tattoo NEW Pliers

Oster 24 Tooth Goat Comb 2 Shearing Blades

Lister Sheep & Alpaca Shearing Blades 2 sets Combs & Cutters

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies