US $225.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Material | Cobalt |

| Flutes | 6-Flute | ||

| Coating | TiCN | ||

| Helix Angle | 30° Helix | ||

| End Type | Square Nose | ||

| Cutting Diameter | 1.5in. | ||

| Brand | UNION BUTTERFIELD | ||

| Shank Diameter | 1.25in. | ||

| Model | 5270086 | ||

| Overall Length | 6.5" | ||

| MPN | 5111033 | ||

| Country/Region of Manufacture | Italy | ||

| UPC | 698464183034 |

Directions

Similar products from End Mills Router & Drill Bits

MACHINIST TOOLS LATHE MILL Lot of End Mill Cutters for Milling Machine

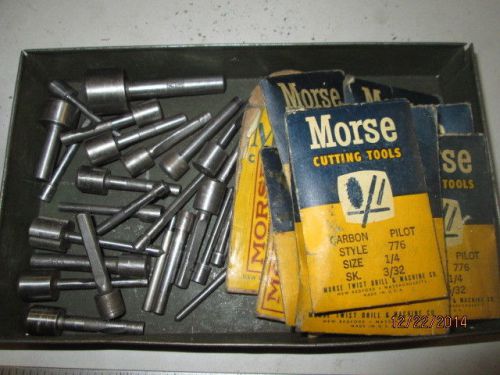

MACHINIST TOOLS LATHE MILL Machinist Lot of Machinist Counter Bore Pilots

PUTNAM - END MILL - 2" X 1 1/4", 8 FLT. USA NOS

NATIONAL TWIST - END MILL - 1 3/4" X 1 1/4" X 2 X 4 1/2" , 6 FLT. USA-NOS

MORIS - HAND TAP - 1 1/8" 7NC, USA - HS - GH4, .

NIAGARA -USA -END MILL - 1.475 CHIP BREAKER, 4 FLT. NOS

2-PCS - HAND TAPS - NORTH AMERICAN, USA, 1 1/4"-7NC, HS, GH8, USED

17- MILL CNC MILLING CUTTERs CUTTING TOOL REAMER MACHINING DRILLING Etc

CTD 6 X 1/2 X 1-1/4 SIDE MILL CUTTER HS

NIAGARA SIDE MILL CUTTER 3 X .174 X 1-1/4

3/32 Carbide endmill for Aluminum | 3 flute Center Cutting 5 PCS Micrograin

1MM X 35MM 2-FLUTE HRC40 CUTTING SOLID CARBIDE FLAT ENDMILL -10x

5/32" OSG Carbide 3/16"-Shank TiALN 4 Flute Double Ended Stub End Mill (M 364)

Union Butterfield 5210084 Cobalt Square Nose End Mill, 6.5 x 1" Diameter

7/8 HSS 2 Flute Double End, End Mill by Cleveland Twist Drill

1Pcs HSS CNC Straight Shank 4 Flute Endmill Milling Cutter 3/16*1/4

5/8 Carbide Endmill 4FL-SE-LG 2-1/4x5 TIALN

1/2" Diameter 2 Flute 90° Deg Point Melin USA Drill End Mill TiCN Carbide #46089

People who viewed this item also vieved

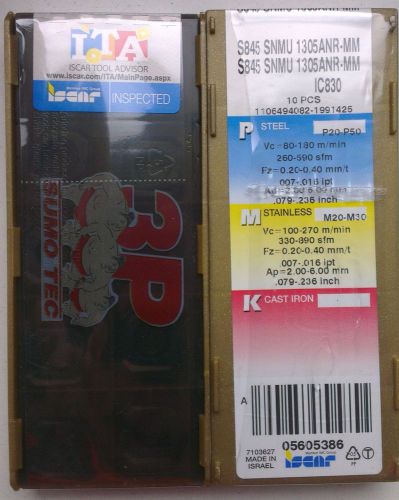

40 pcs Iscar S845 SNMU 1305ANR-MM IC830 milling inserts S845 SNMU 13 05 ANR SXMU

10pcs Iscar DNMA 441 IB66 CBN tip insert DNMA 150604 T hardened steel DNMG 441

3 NEW 6 MM SHANK CARBIDE BURRS FOR CUTTING ALUMINUM. METRIC. MADE IN USA {F761}

1 NEW 6 MM SHANK CARBIDE BURRS FOR CUTTING ALUMINUM. METRIC. MADE IN USA {F760}

(#5040) New Machinist American Made 16mm Chucking Reamer

(#5050) New Machinist American Made 6mm Chucking Reamer

Lot of 4 Sets Vintage Metal Letter & Number Stamps Die Punch ~ Sets Incomplete

Vintage Roper Whitney 8-6 Hole Punch Hand Metal Working Tool

BUTTERFIELD 4" X 1/2" X 1" MILL MILLING CUTTER SLOT BLADE

Cleveland jeweler's slotting saw hss 3 x .45 XL # 428028 LIST # 1319

10 NTK ceramic inserts Square 5/16 x 5/16 x 3/32 thick cnc lathe mill shop T4N

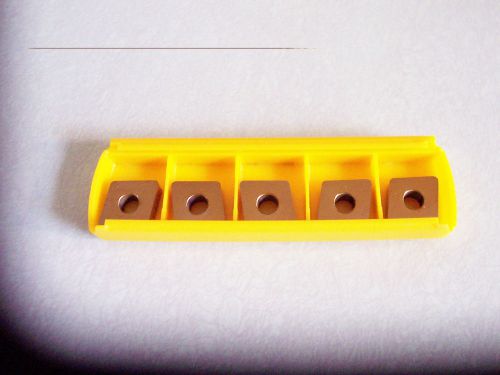

New 5 Pcs - CNGA433FW Grade KY4400 Gold Coated Ceramic Inserts Kennametal

10pc 3*6mm Tungsten Engraving Carbide cutter Burr Shank Cutting edge Rotary

5 pcs Carbide endmill single flute one CNC router bits 4mm x 22mm

Dupont 1-1/8" Type "C" Plain Broach Collar

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies