US $9.99

Directions

Similar products from Instruction Manuals for Metal Cutting

1910 Detrick & Harvey Machine Co.: Drilling, Boring & Milling Machines - reprint

1910 Designing and Cutting Cams, Machinery's Reference Book No. 9 - reprint

PLANER Practice - 1947 ICS (Machine Tools) - reprint

1950s LeBlond Lathes Turn the World Over – Catalog includes Regal Lathes-reprint

1943 - Aircraft Welding: Spot Welding of Aluminum Alloys - reprint

Brown & Sharpe Part Manual Micromaster Surface Grinders (Inv.17919)

Kearney & Trecker operator's manual cat. no. CHC-11

1890s W.F. & John BARNES Co. Metal Working Machinery - reprint

Forming SHeeT METAL with a DRoP HAMMER- US Navy WW2 reprint

WW2 Aircraft Sheet Metal Forming by Hydraulic & Crank Presses & Cast and Molded

Bench Lathe Manufacture and Hand Scraping – Lindsay selection from 1920s

New reprint of 1937 Shaper Job Operations by J. W. Barritt

WW2 US Navy Aircraft Manufacture--Aircraft Tooling: Templets

Reprint of 1943 LeBlond - Running the Regal Lathe - reprint

ARBORS & Work Holding Devices – Metal Cutting - 1914 - reprint

Sales Literature from Chambersburg Engineering 1950s-1970s - ORIGINAL

1912 - Milling Fixtures: Principles of Design & Examples from Practice - reprint

Fellows Complete Equipment for Cutting, Finishing and Testing Gears - REPRINT

Balancing Machine Parts and Miscellaneous Mechanisms, Constructions and Data

TOOL STEEL for the NON-METALLURGIST - 1950 - Crucible Steel Co. - reprint

People who viewed this item also vieved

No. 57 Metal Spinning by Tuells & Painter Reference Book

Carnegie Steel Company Pocket Companion (printed 1920) for engineers

Hossfeld Bender #2 Instruction Manual, Parts Catalog Model # 2, Price List #2

1949 Excel Power Hacksaws Catalog, Covel Mfg. Co.

The Shop Tool Manual - STM 74 - Brown & Sharpe - 1975? Book

Fadal Engineering - VMC Manual Set

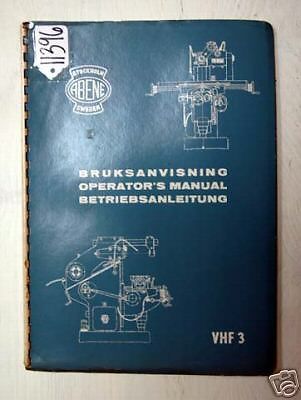

Abene Operators Manual for VHF 3 Milling Machine (Inv.18049)

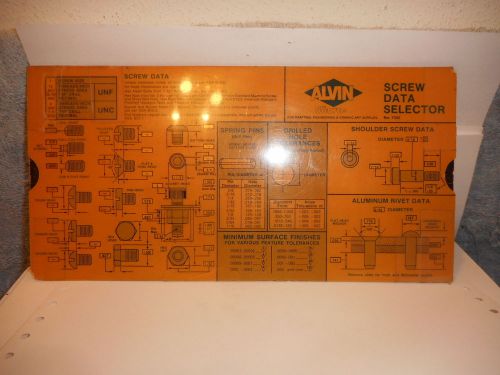

Machinists 2/20USA USA Complet Alvin Screw and bolt and drill calculator

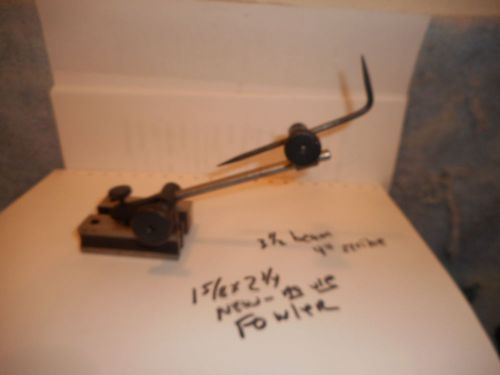

Machinists 2//20 USA Fowler New Small Pattern Surface Gage

Cincinnati Model ER Hydraulic Universal Grinding Machine 1946 Operator's Manual

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies