US $17000

| Condition: | New | Model | flexicone FLR14 |

| Brand | Flexicone | ||

| MPN | Does Not Apply | ||

| Equipment Type | leaching reactor |

Directions

Similar products from Mining & Outdoor Equipment

USB Flexi-Neck LED Light Gold Prospecting Sorting Tool

Prospecting Cleanup Sluice Box Ribbed Matting 30cm 40cm Catch Fine Gold Tools

Flexicone Ceramic Al2O3 drum ball mill FCBM 16

1965 Moser 7000 Gallon T/A Asphalt Tank Trailer # 3070

Vortex ultrasonic air mill pulverizer reactor 2500kg/hour

Rock Crusher Gold Panning Mining Pulverizer Frit Maker Glass Breaker Ore Crusher

FlexiCone for Centrifugal Gold Platinum concentrator with floating bed CCFB170

Cedar Rapids -Universal Jaw Crusher 18” X 24”, Overhead Eccentric Design .

TEREX EVOQUIP BISON 120 MOBILE JAW CRUSHER

NORDBERG 5942-0079 LUBRICATION PUMP "NEW" 1-7/16" SHAFT 3/8" KEYWAY

Centrifugal gold concentrator mining FlexiCone CCFB400 40t/hour with Screen

Centrifugal concentrator Flexicone CCFB170 gold platinum mining prospecting

1965 Moser 7000 Gallon Hot Asphalt Oil Tanker Trailer # 2989

GPE Small Sluice Box (Matting GPE King), (NO dream mat,gold hog, keene)

Titanium Vessel Leaching Reactor 200l gold platinum palladium mining e-waste

OLESI 12 Orbital Jaw crusher rock grinding mill gold mining equipment silver ore

Hard Plastic Black Treasure Scoop for Nugget Recovery and Gold Prospecting

Magcobar Heavy Mud Weight Oil/Well Drilling Brass Vintage Watch Fob slf1A4-1

Flexicone Vortex ultrasonic air mill pulverizer reactor VM150 150kg/hour

Miners Cordless Power LED Helmet Light Safety Head Cap Lamps Torches 4500 LUX A

People who viewed this item also vieved

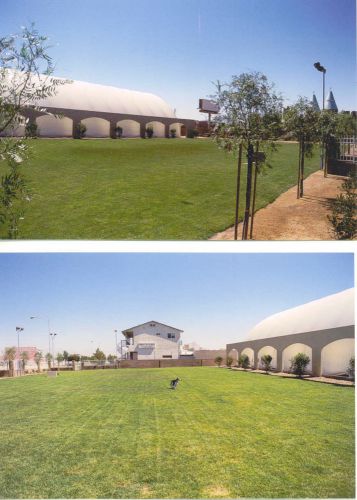

Coverall fabric building 72' x 110'

Steel Factory Mfg 50x50x16 Prefab Auto Repair Commercial Truck Storage Building

METAL, STEEL, BUILDINGS, DELIVERED AND INSTALLED FREE

Ross Concrete Portland Cement Paver Premix Batch Plant (Stock#1146)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies